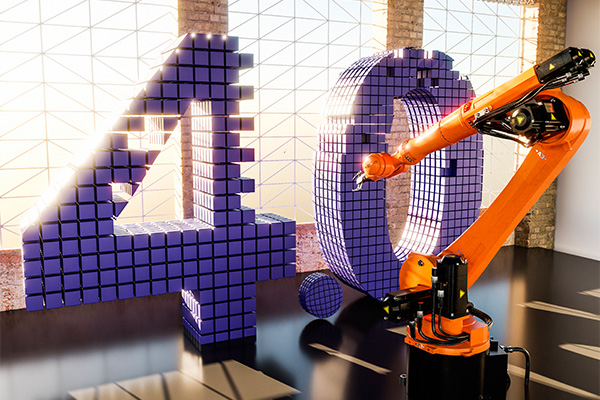

Industry 4.0 Data Collection from Machines

The Fourth Industrial Revolution, known as Industry 4.0, is a concept developed to digitalize production and industrial processes, improve automation, and increase efficiency. This revolution particularly highlights the ability to collect data from machines and analyze this data.

What is Data Collection from Machines?

Industry 4.0 enables machines on production lines to communicate with each other and with higher-level control systems. This allows each machine to share valuable data about production processes. Data collection from machines occurs through sensors, cameras, RFID tags, and other smart devices. These data encompass the condition, performance, energy consumption, and many other factors of the production line.

Optimizing Business Processes with Data Analysis

These collected data enable businesses to monitor, understand, and optimize production processes in real-time. Data analysis is the process of transforming complex datasets into meaningful insights. This helps identify weaknesses in production processes, improve energy efficiency, optimize maintenance processes, and provides many other advantages.

Advantages of Industry 4.0:

- Increased Efficiency: Data obtained from machines allows production processes to be managed more efficiently and effectively.

- Quick Decision Making: Real-time data flow enables managers to make quick decisions.

- Cost Reduction: Data analysis can control energy consumption, waste, and maintenance costs, thereby reducing overall expenses.

- Predictive Maintenance: Data from machines enable predicting equipment failures in advance and performing planned maintenance.

- Competitive Advantage: Industry 4.0 helps businesses gain a competitive edge and maintain leadership in the market.

Industry 4.0’s capabilities in data collection and analysis from machines enable businesses to advance more preparedly into the future. This new revolution transforms not only production processes but also enhances businesses’ overall competitive advantage. In our future blog posts, we will continue to explore other significant aspects of Industry 4.0.